Distribution type peristaltic pump focuses on "distribution".

How to make good use of the distributed peristaltic pump?

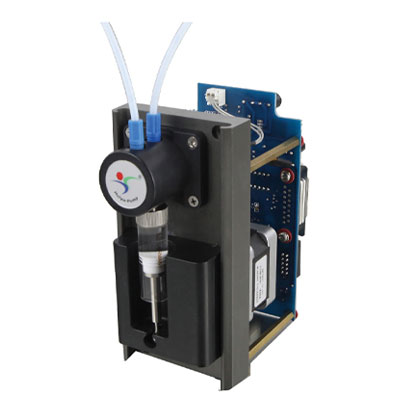

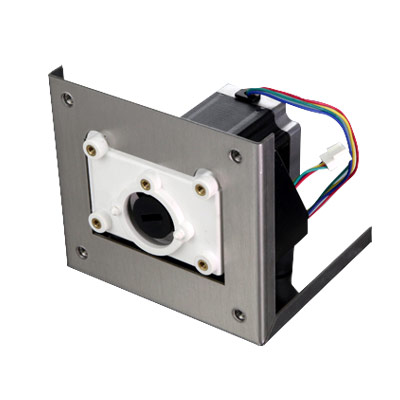

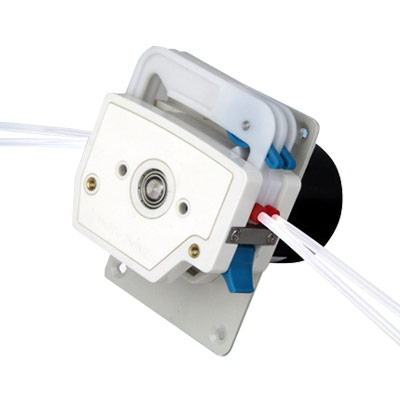

The key is to select the pump head, pump pipe and driver. Specific application requirements determine the functions to be considered when purchasing pump products. For specific needs, we can provide different types and shapes of pump heads, pump pipe materials and pump pipe sizes. Different combinations can meet different fluid transportation requirements

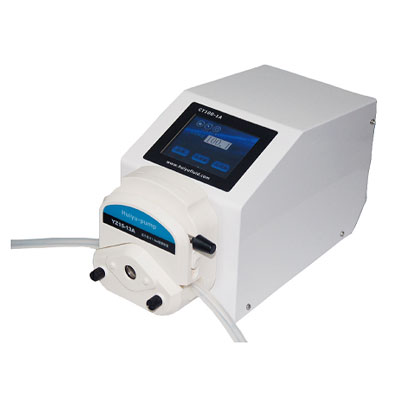

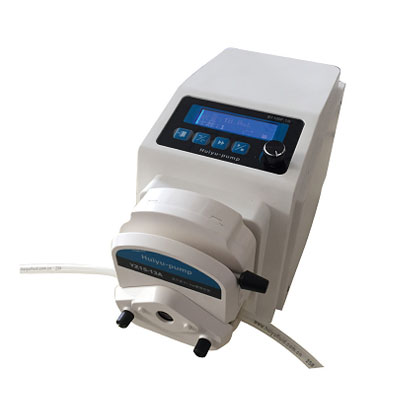

304 stainless steel metal shell, 4.3-inch industrial true color LCD display, intuitive interface, simple touch screen operation, suitable for yz15, yz25, bz25 pump heads, with historical parameter storage function, can timely access common parameter settings, convenient and fast, with independent full speed button, can realize rapid filling and emptying of the pipeline, can control the peristaltic pump through the external control interface, with correction function, and can ensure high accuracy through correction, RS485 communication uses Modbus protocol, which is easy to debug and use.

The distribution peristaltic pump is mainly applicable to the quantitative distribution, accurate measurement and timed feeding of various complex liquids. In addition to the above functions of flow type peristaltic pump, the following functions are added:

1. The user can set the interval time, distribution times, distribution volume and parameters by himself. After setting, the peristaltic pump can automatically complete the specified filling times. This function is mainly applied to the automatic filling equipment on the production line;

2. The distribution peristaltic pump has two working modes: distribution mode and transmission mode. When the transmission mode is selected, the function is completely the same as that of the flow peristaltic pump. When the distribution mode is selected, it has the function of automatic distribution;

3. The distribution peristaltic pump has three distribution modes: time distribution, liquid volume distribution and replication distribution. The first two are easy to understand: time allocation refers to setting allocation according to the length of time. Liquid volume allocation refers to setting allocation according to the size of liquid volume. In the copy allocation setting, the peristaltic pump can automatically record all the parameters of a certain filling. After the filling liquid volume, time and speed are determined, multiple filling can be carried out according to this parameter. The liquid volume of each filling is the same as the set liquid volume.

The distributed peristaltic pump can work in continuous pumping situations, and can solve many difficult pumping problems in fluid transportation. It can transport sewage, suspended solids, corrosive chemicals and other difficult fluids, and the maximum pumping flow can reach 720 l/h (12l/min). Special solutions are required for harsh plant environments. The self filling and dry running capacity of the distributed peristaltic pump can avoid catastrophic failures in pumping of many industrial systems. Common uses: pumping of fuel liquid, etching chemical corrosive liquid, printing ink, laundry chemical solution, grinding liquid, lubricating liquid, etc.

Your location:

Your location:

400-0602-365

400-0602-365