Product Features

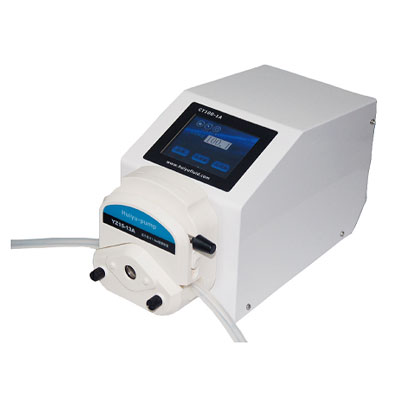

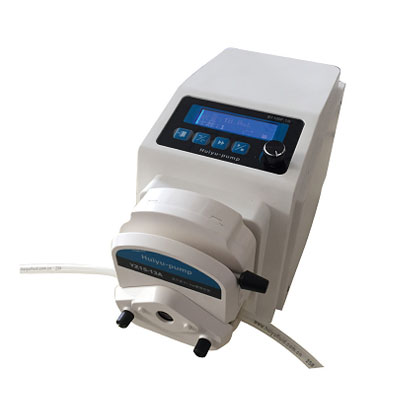

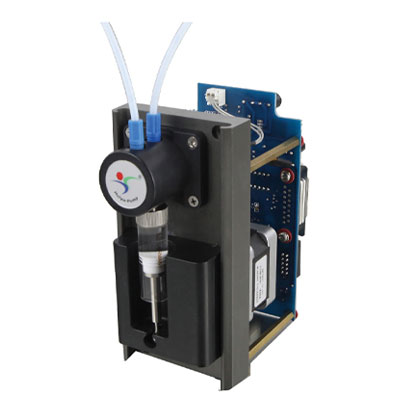

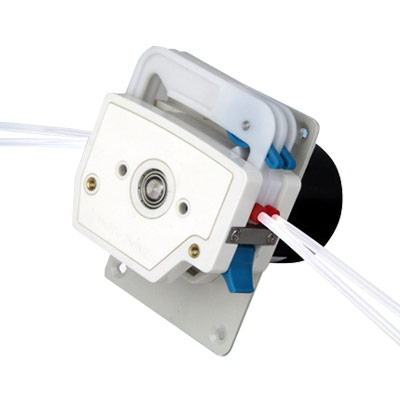

GZ100-3A is a peristaltic pump filling system & controller with intelligent control function independently developed by our company. The filling system consists of 4 sets of basic drive units, which can be expanded up to 32 channels; YZ series and DMD15 pump heads can be installed to provide customers with a variety of options. The controller uses a 7-inch industrial touch screen to clearly display the operation content for the customer.

Features

Any control of the start/stop, left/right turn of each channel of the execution unit.

It can control single or multiple channels for simultaneous evacuation and recycling.

The suckback angle and the suckback time can be set, and all channels are sucked back at the same time.

Provide password function: protect user-set system parameters to prevent misuse.

Provide filling and saving functions for filling solutions.

Four calibration functions are available: proportional adjustment, volume calibration, weighing calibration, and multiple weighing calibration.

Online adjustment function is provided to facilitate the user to adjust the liquid output online.

Provides superior intelligence: The system recommends different filling options for customers to achieve the highest filling accuracy.

The 7-inch touch screen is easy to operate, and the menu-style interface is clear and friendly.

The external communication interface adopts RS485 bus, the baud rate can be set, the parity can be set, and the communication protocol is formulated by Modbus standard protocol.

Technical indicators

The main body is made of 304 stainless steel, which provides high corrosion resistance.

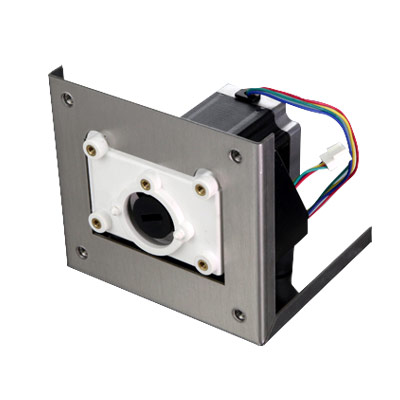

The drive part is made into a separate unit to facilitate the matching with the customer.

The 4-channel is a basic structure that can be assembled in blocks and can be expanded up to 32 channels by cascading.

Each channel address can be easily adjusted through its own mask button and clearly displayed by LED.

It has three operation modes: internal control, external control and communication control, which is suitable for different users.

Each channel has an independent bottle-stop function.

| Pump head model | Filling liquid volume (ml) | Adapter hose | Filling time (s) | Accuracy error | Inner diameter of distribution head (mm) | Reference product (pcs/min) |

| YZ15-1A | 0.3-0.5 | 13# | 1-1.2 | ≤±2% | ≤0.5 | 27-30 |

| 1.0-2.3 | 14# | ≤1.0 | ||||

| 2.6-5.1 | 19# | ≤1.5 | ||||

| 4.6-9.1 | 16# | ≤2.0 | ||||

| 10-19 | 25# | ≤3.0 | ||||

| 15-30 | 17# | ≤3.0 | ||||

| YZ25-1A | 8-17 | 15# | ≤3.0 | |||

| 12-24 | 24# | ≤3.0 | ||||

| DMD15-1A DMD15-2A |

0.1-0.9 | 2×13# | ≤0.5 | |||

| 0.2-2.3 | 2×14# | ≤1.0 | ||||

| 0.5-5.9 | 2×19# | ≤2.0 | ||||

| 2.0-1.0 | 2×16# | ≤3.0 |

400-0602-365

400-0602-365