Product description

Mainly used in automatic filling machinery

Realize pollution-free, accurate medicine and fluid distribution and filling functions

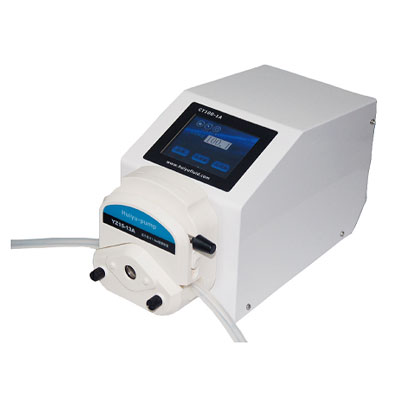

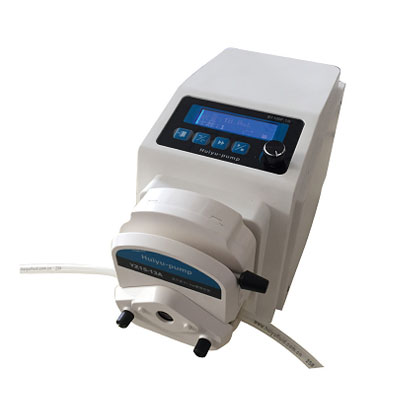

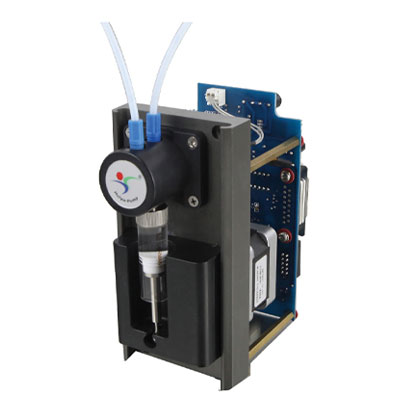

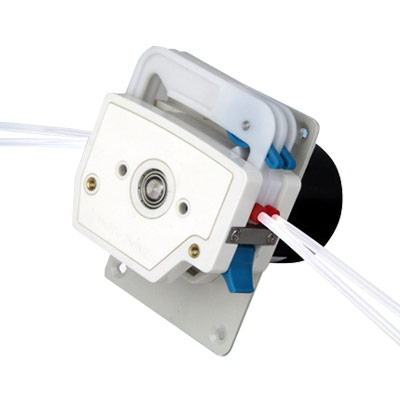

Modular structure, composed of four pumps that can work independently and a filling controller with control function, each unit is independently controlled

Can be stacked to achieve the effect of multi-channel co-filling

Features

◇ The basic structure of 4 channels can be expanded to 16 channels through structural combination

◇ There are two operation modes of online and offline testing, which can solve complex debugging problems conveniently and quickly

◇ Multiple automatic test functions and self-calibration algorithms completely solve the problem of difficult calibration fluid volume, greatly saving debugging time

◇ Arbitrarily control each channel's start/stop, left/right turn, flow setting, flow correction, lack of bottle filling stop function; unified control of the suction angle, etc.; convenient for users to use flexibly. The isolated external control interface realizes the lack of bottle stop Irrigation function

◇ After the system is online, it accepts the control of the start-up operation signal of the filling machine for filling; in the online state, the non-adjustable operation parameter mode is realized, which completely solves the problems of industrial misoperation and accidental collision.

◇ The running time can be set arbitrarily within a certain range, so that users can conveniently choose the appropriate tube according to their actual output to achieve high-precision filling

◇ 128x64 large screen LCD display, clear and friendly, easy to operate

◇ Easy and fast operation is realized through a small number of keys and rotary coding switches

◇ The user can realize the background control of the upper computer through the RS485 interface

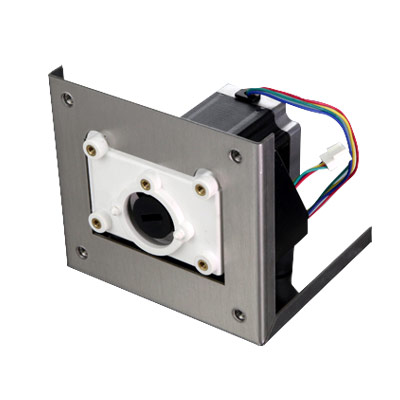

◇ Different pump heads can be replaced

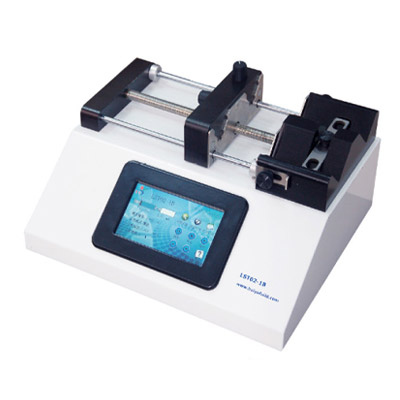

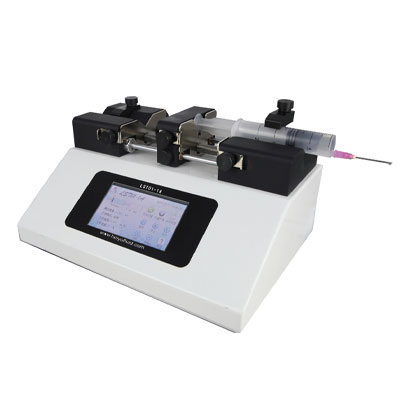

Technical parameter

◇ Volume range of filling: 1ml—100ml

◇ Time range of filling: 0.5—30s

◇ Motor speed:1-600rpm

◇ Speed range: Calculate automatically according to the volume and time of filling.

◇ Back Suction Angle: 0—360°

◇ Calibration: put the actual volume into the pump, it can make a calibration automatically.

◇ Adjust solution amount online: Users can adjust the solution amount and percentage online

◇ Start/stop control : contacts input (stop—filling when lack of bottles)

◇ Memory Function: Repower the pump, it can keep the parameters before power—down.

◇ Communication Interface: RS485

◇ Dimension: 800×200×174 (mm)

◇ Available Power: 220VAC±10%/150W

◇ Working condition temperature: 0℃—40℃

◇ Relative Humidity : <80%

◇ Weight:18.5Kg

◇ IP Grade: IP31

| Pump head model | Adapter hose | Filling liquid volume (ml) | Filling time (s) | Repeatability error | Inner diameter of distribution head (mm) | Reference output (pcs/min) |

| YZ15-1A YZ25-1A |

14# | 2-3 | 1-1.5 | ±1% | ≤1.5 | 30-21 |

| 19# | 3-6 | 1-2 | ≤2.0 | 30-20 | ||

| 16# | 6-12 | 1-2 | ≤3.0 | 30-20 | ||

| 25# | 12-20 | 1-1.6 | ≤3.0 | 30-23 | ||

| 17# | 20-40 | 1-2 | ≤3.0 | 30-20 | ||

| 15# Recommended with viscosity | 12-20 | 1-1.6 | ≤3.0 | 30-23 | ||

| 24# Recommended with viscosity | 20-40 | 1-2 | ≤3.0 | 30-20 |

400-0602-365

400-0602-365