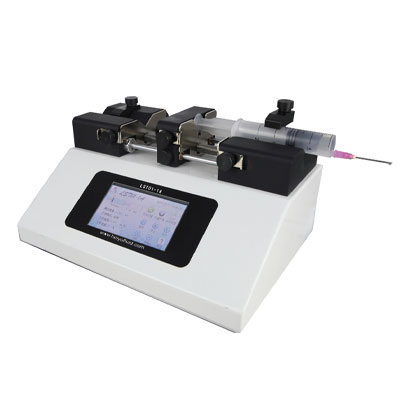

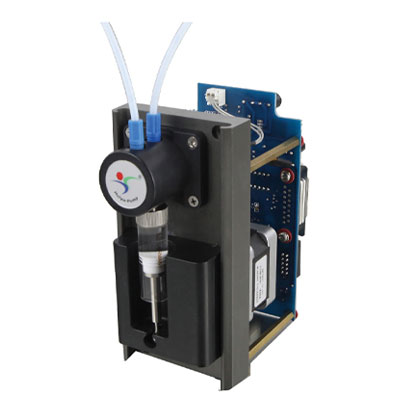

Product Features

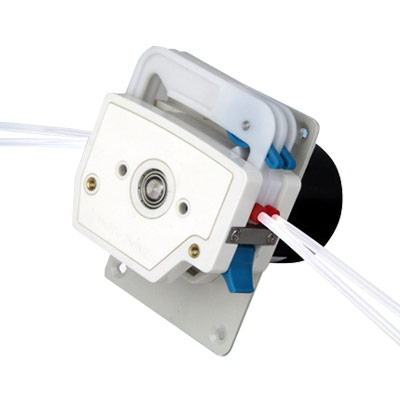

The stainless steel syringe is made of 316 stainless steel and Viton (or perfluorinated O-ring seal). Strong temperature and pressure resistance. Suitable for corrosive, viscous liquid handling, high pressure applications, etc.

Main application industries: pharmaceutical, biological, chemical, petrochemical, nervous system, product development, government, food and beverages, etc.

Specific applications such as: reactor dosing; viscous liquids, etc.

Specifications and sizes can be customized.

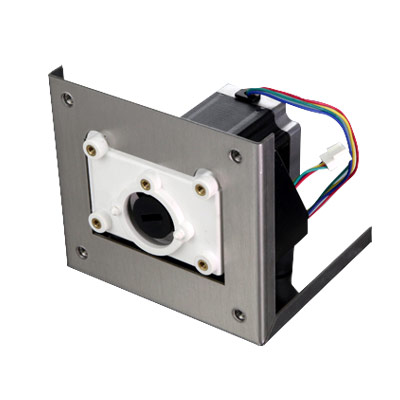

Features

304 stainless steel and semi-fluorine sealing ring are used to provide better chemical resistance and can adapt to more chemical reagents

Can withstand higher temperatures: -15℃~200℃

The joint form can be changed, and the 5/16-inch SWAGELOK joint reduces the volume of the dead zone;

Using high-intensity laser electron beam welding

The seal can be replaced

Repeated use after high temperature and high pressure

400-0602-365

400-0602-365