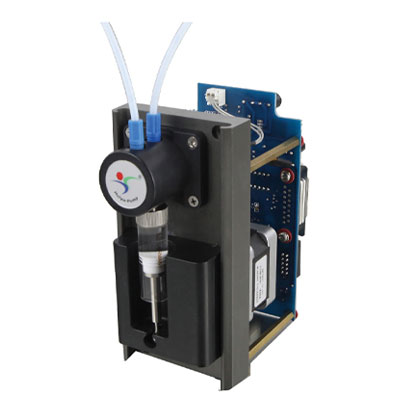

Selection of peristaltic pump driver:

Select the drive motor according to the required control type. Most pump manufacturers have considered the interchangeability between the pump head and the driver to a certain extent. This is particularly important in the early stages of peristaltic pump testing and various studies.

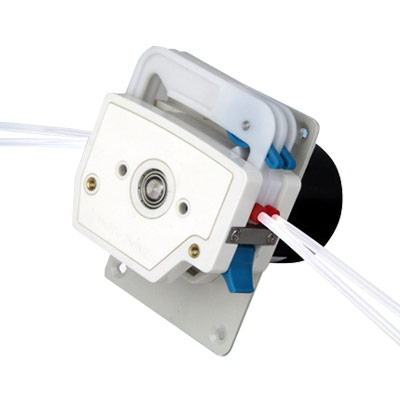

Fixed speed drive

It represents a simple fluid delivery method. The pump system can always maintain a constant operating speed during the entire operation period. Sometimes the flow can be changed by changing the size of the pump tube.

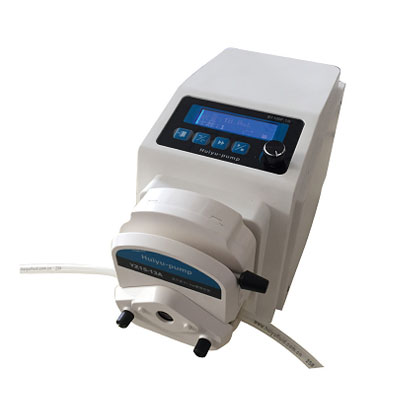

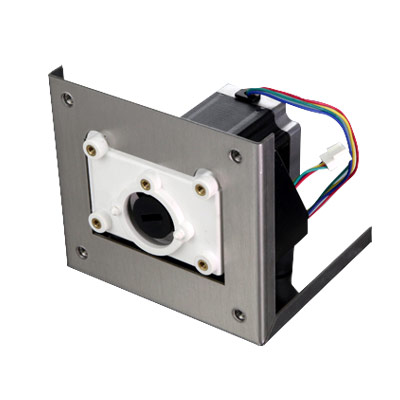

Variable speed drive

In some applications where a larger flow adjustment range is particularly required, a variable speed drive can be considered. Pumping the correct flow at the correct time requires certain skills. Variable speed drives can usually be continuously variable between the minimum and maximum speeds. Motor speed, reduction ratio, and percentage speed adjustment are three key factors to be considered when selecting a drive. The reversal feature of the driver helps to clean the suction line before replacing the pump tube.

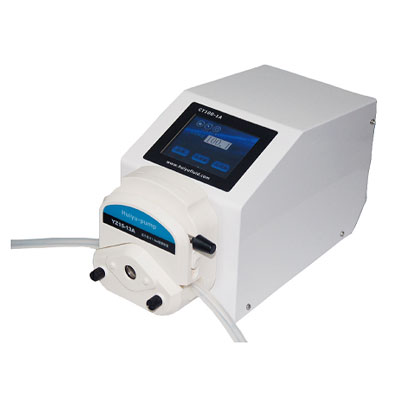

Digital display

The controller with microprocessor improves the operation level of the pump. Strict pipeline control and load adjustment can ensure the smooth delivery of fluid. Simply adjust your pump system to display the flow rate and other important setting guidelines on the digital display.

remote control

It has become increasingly important to integrate peristaltic pumps into automation systems for laboratory or industrial control. Controllable functions include: start or stop, reversal, pump filling, distribution or copying, speed, etc. You can choose an analog control interface (such as DC voltage, current, or contact closure), or choose a digital control interface (such as RS-232).

Your location:

Your location:

400-0602-365

400-0602-365