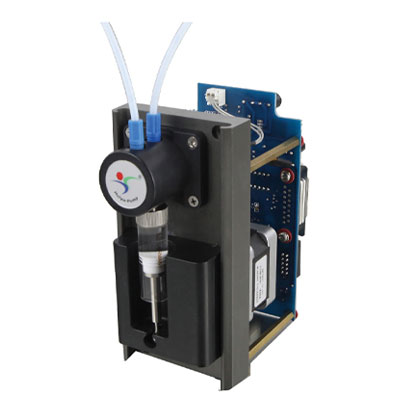

In many applications, the choice of pump head is critical. The correct use of the pump head can avoid many unnecessary failures during start-up and operation. The following are the factors to be considered when selecting the function of the peristaltic pump head:

Flow range

The requirements for flow determine the size of the pump tubing and the type of pump head in a specific application.

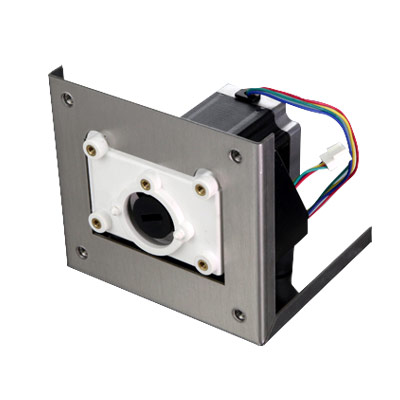

Material of pump head

The material of the pump head should be resistant to chemical corrosion, and the bearing should be protected by a shell to deal with corrosive fluids or harsh environmental conditions. The pump head with a high-performance plastic shell has the advantages of light weight, strong chemical resistance, and low price.

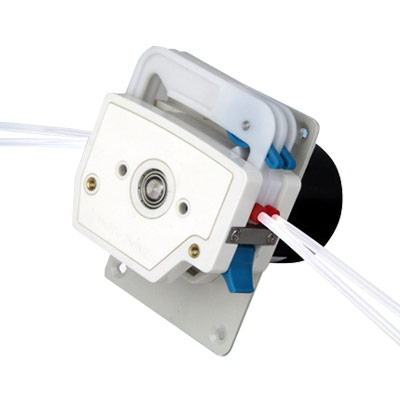

Number of rollers

When the number of rollers on a rotor of a given size decreases, the flow rate increases; but the pulsation degree also increases. When the number of rollers is increased, the pulsation is reduced and the distribution accuracy is increased; but the flow rate is reduced, and the service life of the pump tube is shortened. In a certain period of time, the number of rollers that press through the pump tube increases, and the vacuum performance and pressure performance of the pump tube also increase.

Easy to assemble and disassemble

The method of assembling and disassembling the pump tube can greatly affect the user's satisfaction with the pump. The pharmaceutical, food supply, and printing processes all require frequent replacement of pump tubes (such as every shift or once a day). In order to save time when cleaning or changing products, easy-to-install pump heads can be used, which can save expensive labor costs (see Figure 2).

Applicable pump tube size number

The pump head type that can only be adapted to one pump tube size can play the performance of this size (such as the ability to withstand pressure and vacuum, flexural yield limit, etc.). The pump head that can be adapted to a variety of pump tube sizes has a more average performance. This allows the same pump head to have a larger pumping flow range.

Fixed or adjustable pump tube locking degree

How much is the degree of locking of the pump tube to make the pump work normally? The advantages of fixed-locking peristaltic pumps are that they perform well in repeated use and reduce the chance of operator errors. When used with precision extruded pump tubing, it can provide excellent repeatable performance.

Adjustable locking peristaltic pumps can increase the degree of locking of the pump tube during self-priming, or reduce the degree of locking in low-pressure applications to extend the service life of the pump tube. This method can also achieve the purpose of fine-tuning the flow. This is especially useful for flow synchronization of multi-channel pump heads.

Special pump head

It can provide unique pump head configurations for special market needs, such as various special pump heads for smooth delivery requirements, fast volume distribution requirements, long-distance pumping requirements, or ultra-strong chemical corrosion resistance requirements.

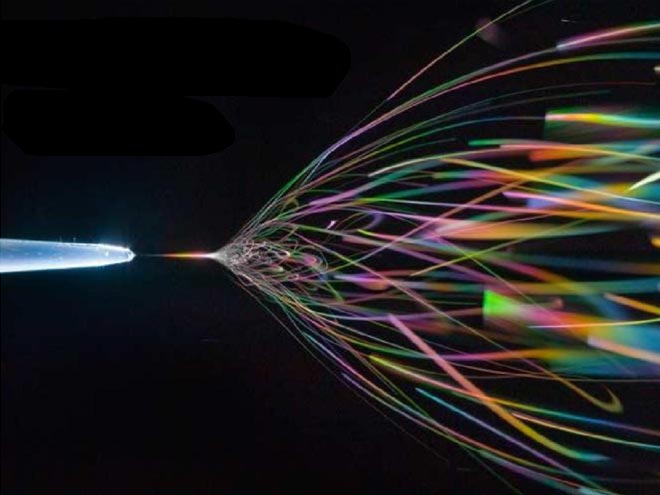

This type of pump head can give full play to the advantages of a certain special function. For example, by combining two fluid channels with complementary pulsation, the fluid delivery process can become more stable; and the use of PTFE pump tubing can obtain super chemical corrosion resistance; combine a special pump tube group with a special pump head Matching can transport strong chemical corrosive fluid or high purity fluid.

Special pump head

It can provide unique pump head configurations for special market needs, such as various special pump heads for smooth delivery requirements, fast volume distribution requirements, long-distance pumping requirements, or ultra-strong chemical corrosion resistance requirements.

This type of pump head can give full play to the advantages of a certain special function.

For example, by combining two fluid channels with complementary pulsation, the fluid delivery process can become more stable (such as DMD25 pump head); and the use of PTFE pump tubing can obtain super chemical corrosion resistance; a special pump tubing set Matching with a special pump head can deliver strong chemically corrosive fluids or high-purity fluids.

Your location:

Your location:

400-0602-365

400-0602-365