With certain elasticity, the hose can quickly recover its shape after being compressed radially (Shore hardness: 40-80).

Have a certain ability to withstand pressure.

No leakage (good air tightness)

Low adsorption, temperature resistance, resistance to aging, no swelling, corrosion resistance, low precipitation, etc.

Choosing the right pump tubing is as important as choosing the pump head. Conventional pump heads can be adapted to a variety of pump tube sizes. Special pumps usually require special-shaped pump tubing, hoop pump tubing components, or special joints.

The types of hose materials available on the market are extremely diverse, and the prices vary greatly. But only a few can be used as pump tube materials. Some materials are similar in appearance, but the pumping performance is quite different. A good pump tube should have excellent tensile and anti-extrusion properties. Most pump manufacturers provide a variety of pump tubing that has been tested and verified. These pump tube materials have a stable flexural yield limit, which can ensure the stability of the flow.

The pump tube material should be selected according to the application requirements and the operator's preference. However, special attention should be paid to the satisfaction of the following indicators:

Chemical compatibility

When choosing a peristaltic pump for pumping corrosive fluids, the key is to choose the correct pump tubing material. Choosing the wrong pump tube can lead to dangerous situations, possibly destroying equipment and endangering people. Please consult the chemical compatibility table for each application provided by the pump and pump tubing manufacturer. Experiment with the pump before using new or unmarked chemical substances. Dip a short section of pump tubing into the fluid. Check the changes in the size, color, weight and strength of the pump tube. If possible, test the pump tube in the pump before stretching it for use. When the pump tube is squeezed, it will bend, which will knead the chemical substance into the tube wall and accelerate the aging and disintegration of the tube.

Non-polluting

In many applications such as laboratory research, pharmaceuticals, and biotechnology product production, fluid isolation is essential. A large number of studies have demonstrated that silicone tubes and silicon-based materials will not chemically react with various biological materials. There are other types of materials that also have this performance, and can meet the requirements of USP Class VI. Some pumps use pump tube assemblies made of inert PTFE tubing.

Note: After long-term operation, some particles in the pipe will separate out and fall into the fluid. Experts call this the "stripping phenomenon". In some applications, such particles can be observed with the naked eye. In order to minimize the peeling phenomenon, the frequency of pipe replacement should be increased.

Flexural resistance

The ability of different pipes to withstand repeated rolling by rollers is also different. Generally speaking, the combination of specific pump tube size, pump tube material, pump head type, and operating speed determines the service life of the pump tube. The service life of the pump tubing, or the flexural yield limit in the pump, is the primary consideration before putting into a new application. Nowadays, with the use of thermoplastic elastomer (TPE) in the system, it is very common for the pump tube to run for more than 500 hours.

In a particular application, the performance of the pump is very stable. Choosing a pipe with greater resistance to flexing, using a thicker pipe wall, and/or choosing a larger pump and using a lower operating speed can extend the mission of the pump pipe.

Clarity

For some applications, it is very valuable to be able to observe the movement of the fluid through the pipeline in order to clearly understand the working process of the pump or dry operation. But on the other hand, opaque tubing is good for some photosensitive fluids.

Hardness Tester

The hardness of the pipe wall is critical to determining the pumping capacity of a particular pipe. If the pump tube is too soft, it will be easily damaged; if the pump tube is too hard, the pump will not work. Hardness tester (such as Shore A, etc.) can be used to determine the physical properties of specific pipes.

Fluid pressure

Fluid pressure usually restricts the pump tube’s ability to deliver pressure fluid. Most peristaltic pumps use unsupported pipes. The pressure limit of this type of pump tube is 2 to 3 bar (30 to 45 pounds per square inch). Some of the larger pumps on the market use supporting pipes (with braided reinforcement). The pump tubing immersed in the lubricating fluid can withstand pressures of up to 15 to 20 bar (300 pounds per square inch).

-

Products

-

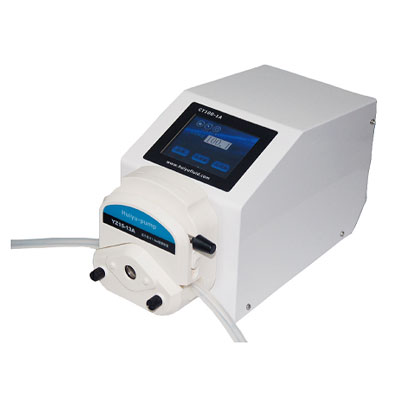

BT100J-1A

BT100J-1AFlow range:≤380ml/min

-

BT300J-1A

BT300J-1AFlow range:≤1140ml/min

-

WT600J-1A

WT600J-1AFlow range:≤6000ml/min

-

YT600J-2A

YT600J-2AFlow range:≤13000ml/min

-

FB600-1A

FB600-1AFlow range:≤13000ml/min

-

BT100L-1A

BT100L-1ASingle channel flow range:≤380ml/min

-

BT300L-1A

BT300L-1AFlow range:≤1140ml/min

-

WT600L-1A

WT600L-1ASingle channel flow range:≤12000ml/min

-

The CT100-600F series

The CT100-600F series -

CT100-1A

CT100-1AFlow range:≤900ml/min

-

BT100F-1A

BT100F-1AFlow range:≤380ml/min

-

BT300F-1A

BT300F-1AFlow range:≤1140ml/min

-

WT600F-2A

WT600F-2ASingle channel flow range:≤6000ml/min

-

WT600F-1A

WT600F-1ASingle channel flow range:≤13000ml/min

-

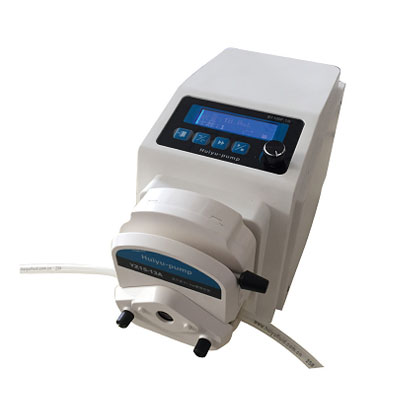

YZ15/25

YZ15/25Flow range:≤2200ml/ min

-

Industrial easy load pump head YZ35

Industrial easy load pump head YZ35Flow rate range:?≤13000ml/min

-

Multi-channel pump head

Multi-channel pump headSingle channel flow range:≤48ml/min

-

Quick load pump head—KZ25

Quick load pump head—KZ25Flow range: ≤6000ml/min

-

LST01-1B laboratory syringe pump

LST01-1B laboratory syringe pumpFlow range:?0.001μl-86.699ml/min

-

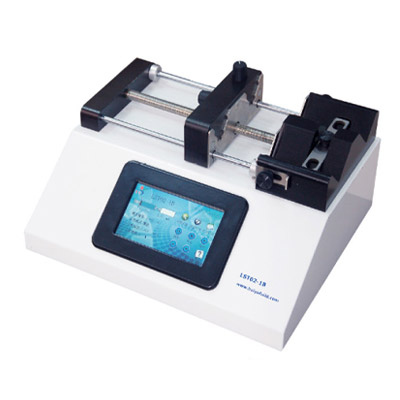

LST02-1B laboratory syringe pump

LST02-1B laboratory syringe pumpFlow range:?0.001μl-86.699ml/min

-

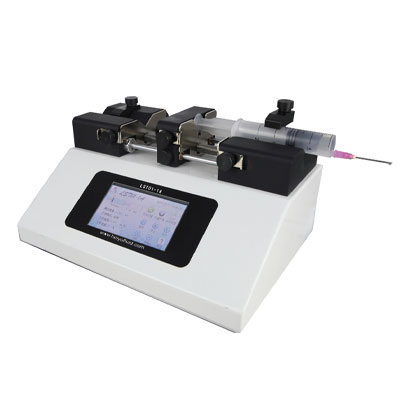

LST01-1A micro volume syringe pump

LST01-1A micro volume syringe pumpFlow range: 0.001μl-14.068ml/min

-

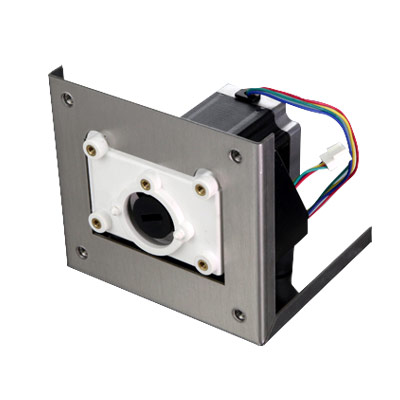

MSP30-1A

MSP30-1AStroke length: 3000 steps (30mm)

-

MSP60-1B syringe pump

MSP60-1B syringe pumpStroke length:6000 steps (60mm)

-

MSP30-2A

MSP30-2AStroke length:1000 steps (30mm)

-

MSP60-3A

MSP60-3AStroke length:6000 steps (60mm)

-

Micro piston pump

Micro piston pumpPlunger stroke:12.5mm(2000)step

-

Large volume filling system

Large volume filling system -

GZ100-3A

GZ100-3A0.1-9999.99mL

-

GZ100-1A

GZ100-1A0.5-100mL

-

GZ30-1A

GZ30-1A0.1-30mL

-

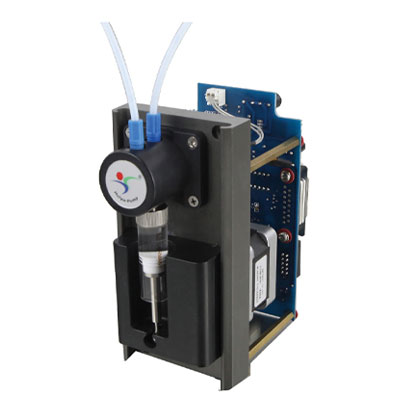

OEMDSK100-07/WX10

OEMDSK100-07/WX10Flow range: ≤40ml/min

-

OEMDSK100-01

OEMDSK100-01Flow range: ≤170ml/min

-

OEMDSK100-600

OEMDSK100-600≤2200ml/min

-

OEMDSK300-01

OEMDSK300-01Flow rates:≤1140ml/min

-

OEMDSK60-02/WX10-1A

OEMDSK60-02/WX10-1AFlow range:≤24ml/min

-

JY15-1A

JY15-1AFlow range:≤170ml/min

-

OEM300J-01

OEM300J-01flow rate:≤1140ml/min

-

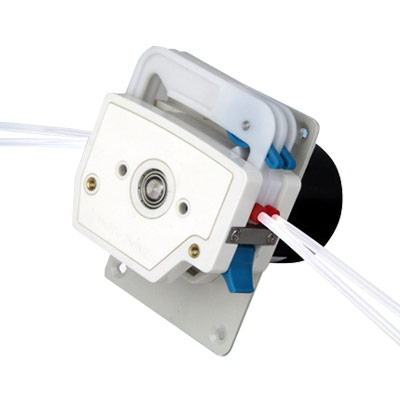

OEMDS100-600

OEMDS100-600Flow range:≤2200ml/min

-

OEMMA60-1A/TH15

OEMMA60-1A/TH15Flow range: ≤184ml/min

-

OEMMA60-03/DG-2

OEMMA60-03/DG-2Flow range: ≤48ml/min

-

OEMDD120-01/KZ25-1A

OEMDD120-01/KZ25-1AFlow range: ≤6000ml/min

-

-

Industry

-

Biomedicine

-

Laboratory research field

-

Water treatment industry

-

Chemical Industry

-

Food and beverage industry

-

Medical testing industry

-

Mining and metallurgical industries

-

Environmental protection industry

-

Ink printing industry

-

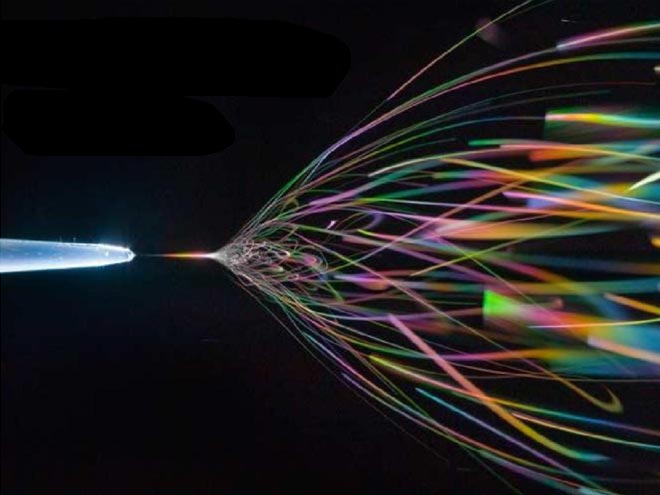

High voltage electrospinning

-

Biomedicine

-

Laboratory research field

-

Water treatment industry

-

Chemical Industry

-

Food and beverage industry

-

Medical testing industry

-

Mining and metallurgical industries

-

Environmental protection industry

-

Ink printing industry

-

High voltage electrospinning

-

Biomedicine

-

Laboratory research field

-

Water treatment industry

-

Chemical Industry

-

Food and beverage industry

-

Medical testing industry

-

Mining and metallurgical industries

-

Environmental protection industry

-

Ink printing industry

-

High voltage electrospinning

-

Biomedicine

-

Laboratory research field

-

Water treatment industry

-

Chemical Industry

-

Food and beverage industry

-

Medical testing industry

-

Mining and metallurgical industries

-

Environmental protection industry

-

Ink printing industry

-

High voltage electrospinning

-

Biomedicine

-

Laboratory research field

-

Water treatment industry

-

Chemical Industry

-

Food and beverage industry

-

Medical testing industry

-

Mining and metallurgical industries

-

Environmental protection industry

-

Ink printing industry

-

High voltage electrospinning

-

Biomedicine

-

Laboratory research field

-

Water treatment industry

-

Chemical Industry

-

Food and beverage industry

-

Medical testing industry

-

Mining and metallurgical industries

-

Environmental protection industry

-

Ink printing industry

-

High voltage electrospinning

-

Biomedicine

-

Laboratory research field

-

Water treatment industry

-

Chemical Industry

-

Food and beverage industry

-

Medical testing industry

-

Mining and metallurgical industries

-

Environmental protection industry

-

Ink printing industry

-

High voltage electrospinning

-

Biomedicine

-

Laboratory research field

-

Water treatment industry

-

Chemical Industry

-

Food and beverage industry

-

Medical testing industry

-

Mining and metallurgical industries

-

Environmental protection industry

-

Ink printing industry

-

High voltage electrospinning

-

- Service

- News

- Company

Your location:

Your location:

400-0602-365

400-0602-365