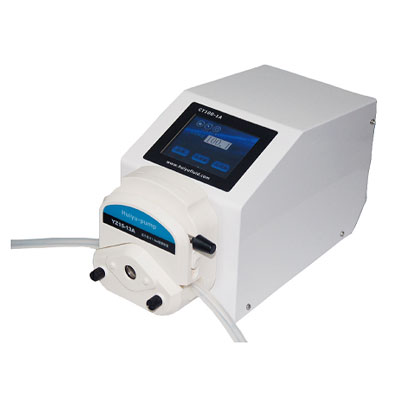

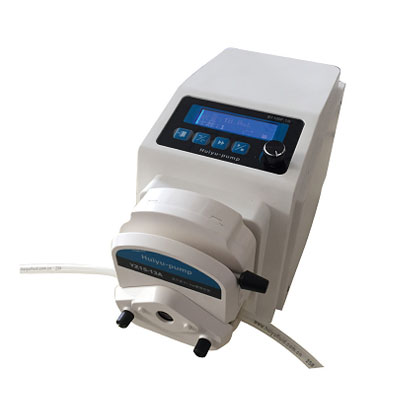

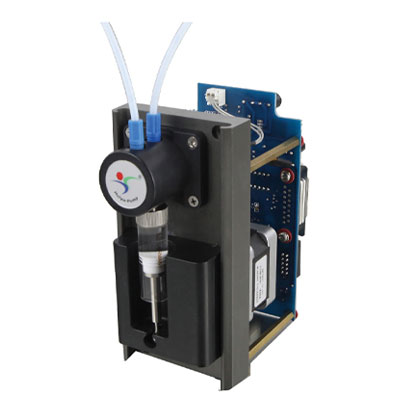

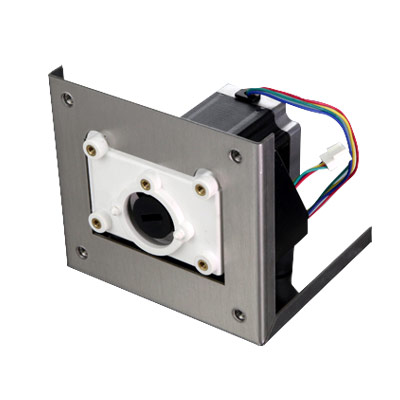

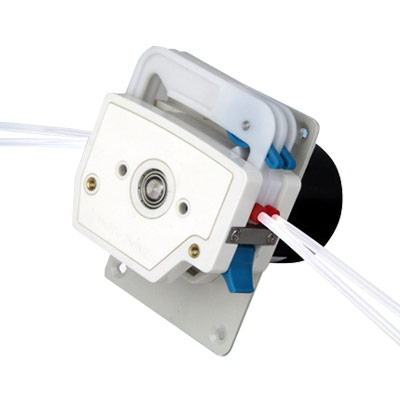

The filling peristaltic pump is composed of a main drive system, a bottle feeding system, a pump head group and a filling distribution group. It is composed of a plug system composed of a plug group and a plugging group, and an electrical control system. The structure is novel and reasonable.

The pump source of the filling peristaltic pump adopts a peristaltic pump, which makes full use of the characteristics of the peristaltic pump, and has a simple structure. The pump body has no place to contact the liquid medicine, so there is no need to clean and disinfect the pump body. The filling peristaltic pump is driven by a stepping motor or a servo motor. The PLC control achieves easy adjustment of the filling volume. Only the corresponding number can be input. It can be adjusted at any time under working conditions. The accuracy can reach ±2%. The modular structure is adopted. Each unit has 4 channels, which can be expanded to 4 units (16 channels), sharing one controller.

The advantages of filling peristaltic pumps:

1. No pollution: the fluid only touches the pump tube, not the pump body

2. High precision: repeatability, stability and high precision

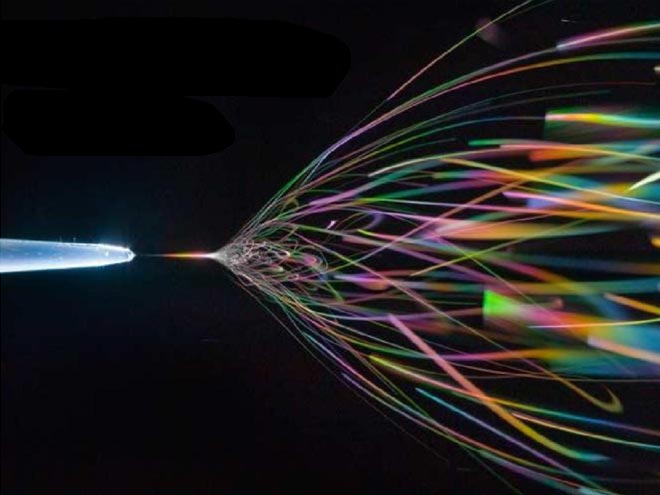

3. Low shear force: an ideal tool for conveying shear-sensitive and aggressive fluids

4. Good airtightness: good self-priming ability, can be idling, can prevent backflow

5. The maintenance of the peristaltic pump is simple: no valves and seals, and the hose is a vulnerable part

6. Can pump liquid, gas, solid or multiphase mixture

Applicable scope of filling peristaltic pump:

The filling peristaltic pump can fill most types of liquids, including liquids with high viscosity. Such as: various pharmaceuticals, chemicals, oils, cosmetics, food and other non-granular liquids; high filling accuracy, suitable for laboratory use.

400-0602-365

400-0602-365