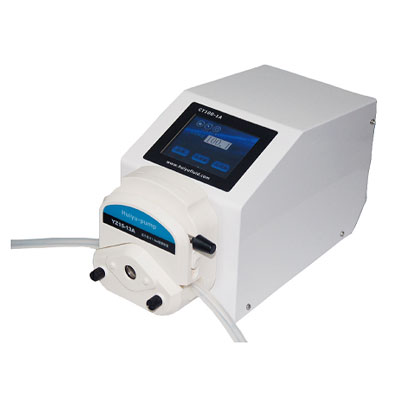

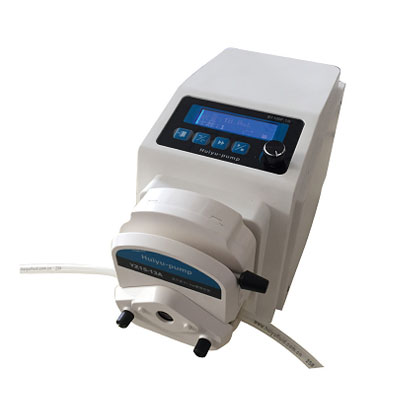

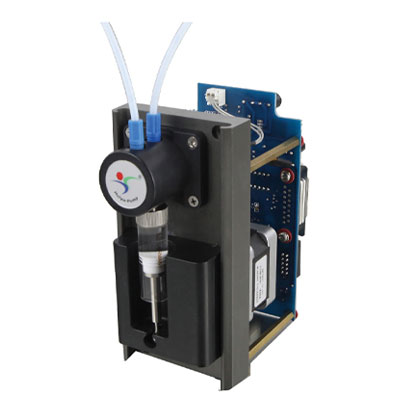

The four bases for the selection of peristaltic pumps peristaltic pumps use rotating rollers to squeeze the hose to transport fluid. As the fluid only flows in the hose, it does not contact the pump body, and will not cause cross pollution. At the same time, the conveying accuracy is high and the shear effect is small. As peristaltic pump driver is a high-precision equipment integrating machinery, electronics and software, which can receive a variety of external control signals to achieve external signal control, it is often used as an ideal equipment for industrial supporting and distributed control. Then I'll give you a brief introduction of the 4 basis for the selection of peristaltic pump.

1. Determination of requirements

Since the model is selected, you should first determine your own needs, mainly including: flow size, accuracy requirements, transmission medium, channel number, pressure range, suction range and control mode.

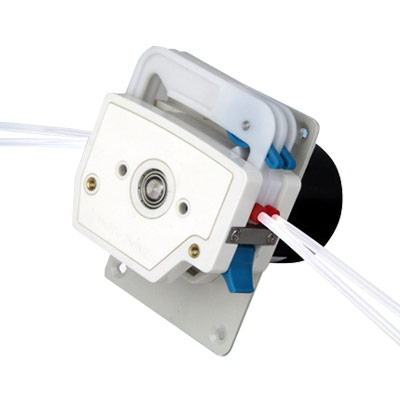

2. Selection of pump head

Number of channels: determine the number of channels according to the workload demand.

Number of rollers: the number of rollers is the key factor to determine the pulsation, and the number of rollers depends on the pulsation requirements.

Disassembly method: simple and convenient disassembly method is a good choice.

3. Selection of hose

Inner diameter: the inner diameter is proportional to the flow.

Wall thickness: the greater the pressure, the greater the wall thickness is required.

Material: special medium, special function hose shall be selected, such as corrosion resistance, acid resistance, strong acid resistance, organic resistance

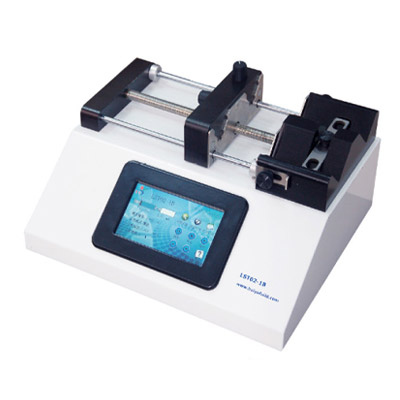

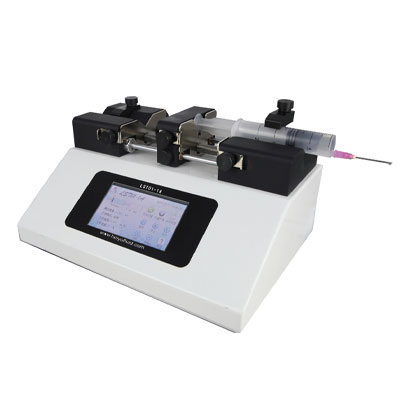

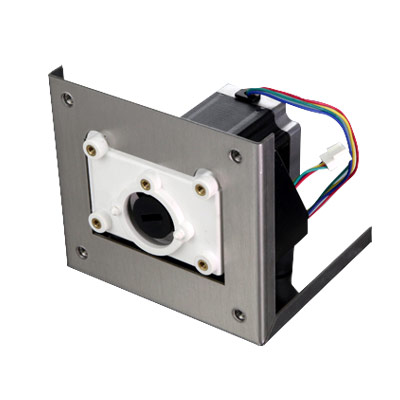

4. Driver selection

Speed: the speed is proportional to the flow. Refer to the parameter diagram.

Accuracy: select the corresponding rotary actuator for different accuracy.

Protection grade: different environments have different requirements for product protection grade. For example, if the working environment requires waterproof and dustproof, the driver corresponding to the IP grade shall be selected.

400-0602-365

400-0602-365