The peristaltic pump is used to obtain the required flow rate. Therefore, according to the operation and use of the pump, it is divided into: 1. Speed-regulating peristaltic pump: It has the basic control function of the peristaltic pump, displaying the speed, start and stop, direction, speed adjustment, and filling row. Empty, power-down memory, external control input and other functions.

1. Classification

The peristaltic pump is used to obtain the required flow. Therefore, according to the operation and use of the pump, it is divided into:

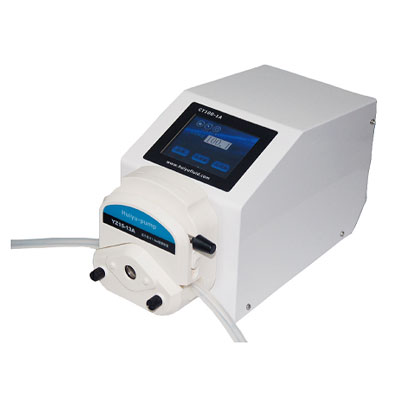

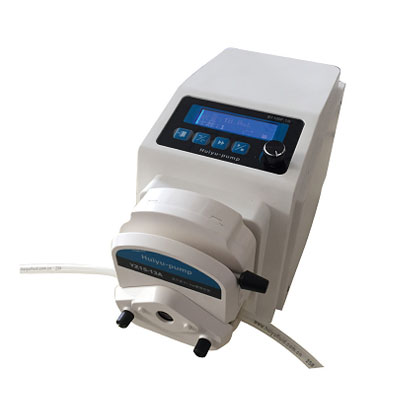

1. Speed-regulating peristaltic pump: It has the basic control functions of a peristaltic pump, displaying speed, start and stop, direction, speed adjustment, filling and emptying, power-down memory, external control input and other functions.

2. Flow-type peristaltic pump: In addition to basic functions, functions such as flow display, flow correction, and communication are added.

3. Distributed peristaltic pump: In addition to basic control functions, it adds functions such as flow display, flow correction, communication, liquid volume distribution, suction, and output control.

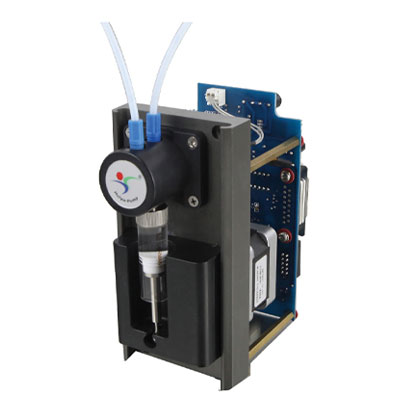

4. Customized (OEM) peristaltic pump: With a series of pump heads with different flow ranges, customers can design different drive circuits for supporting use according to their own equipment requirements.

2. System composition

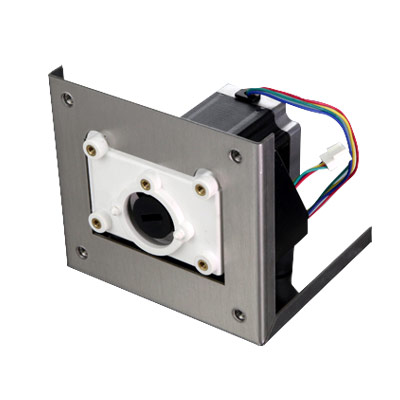

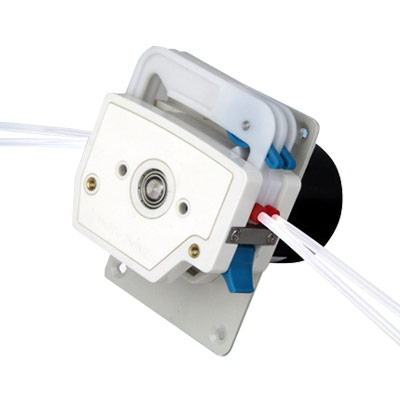

The peristaltic pump system consists of three parts: the peristaltic pump driver, the peristaltic pump head, and the peristaltic pump tube.

Third, the selection of the components of the peristaltic pump

Selection tube

As a condition of peristaltic pump hose

Has a certain degree of flexibility, that is, the hose can quickly recover its shape after being compressed in the radial direction

Have a certain ability to withstand pressure

No leakage (good air tightness)

Low adsorption, good temperature resistance, not easy to age, no swelling, corrosion resistance, low precipitation, etc.

Choose pump head

Choice of single or multi-channel fluid delivery

Is it easy to replace the hose

Is it easy to fix the hose

The pressure tube gap is fine-tuned by a ratchet or other means to adapt to different wall thickness hoses or to achieve fine-tuning of pressure

Roller selection: 6-roller structure has a slightly larger relative flow rate; 10-roller structure has a smaller fluid pulsation amplitude

Whether the trigger structure is dexterous and whether it is convenient to open the card

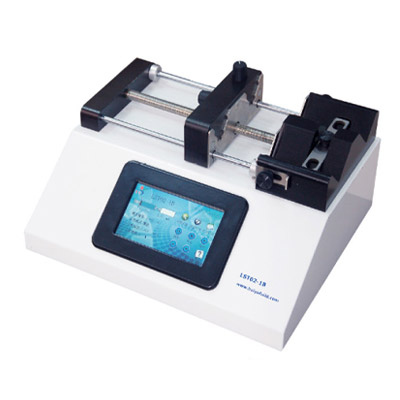

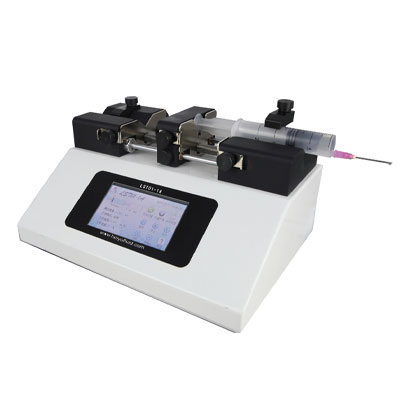

Select drive

Do you need flow control

Do you need liquid volume distribution

What is the size of the flow range

Whether the overall structure is reasonable and whether the operation is convenient

Whether the flow accuracy and liquid volume accuracy meet the requirements

Special requirements: protection level, explosion-proof level, etc.

External control requirements: Peristaltic pump equipment matching, operation mode, etc., such as RS232, RS485 communication, 0-5V external control speed regulation, pulse speed regulation, etc.

400-0602-365

400-0602-365