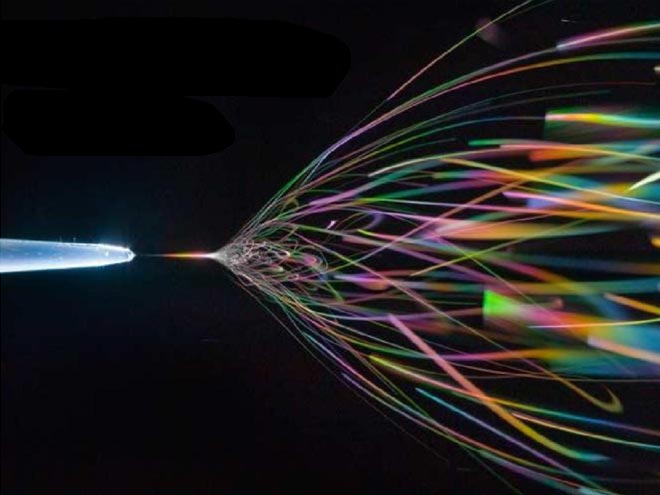

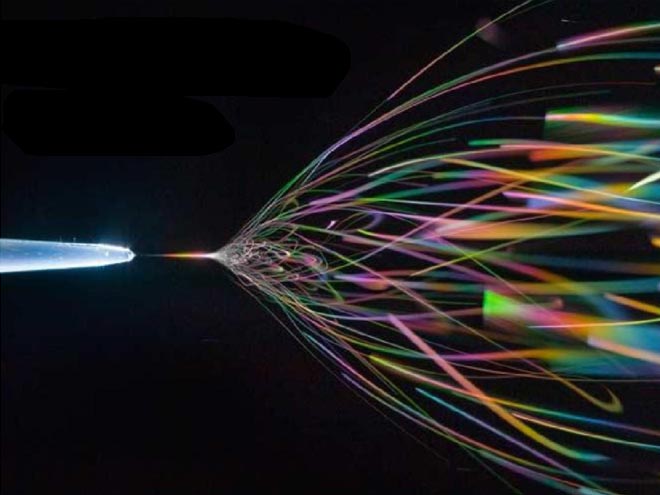

High-voltage electrostatic spinning technology is a method of preparing nano-micron fiber materials by using the breakdown effect of a high-voltage electrostatic field on a polymer solution. The end of the cone forms a jet and is stretched in an electric field to form a non-woven nanofiber on the receiving device. Electrospinning can prepare fibers with a diameter of tens to hundreds of nanometers. The products have high porosity and large specific surface area, diversified components, uniform diameter distribution, and are very useful in the fields of biomedicine, environmental engineering and textiles. High application value.

The main factors affecting electrospinning are the choice of solvent, the stability of the injection speed, the concentration of the solution, the intensity of the applied electric field, and the distance between the spinneret and the receiver.

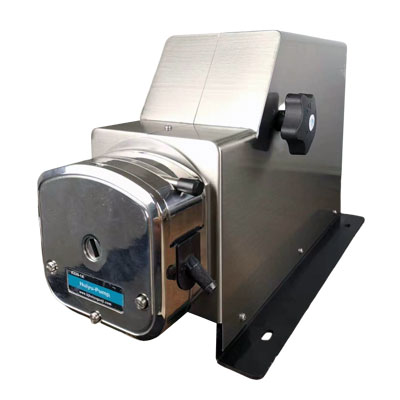

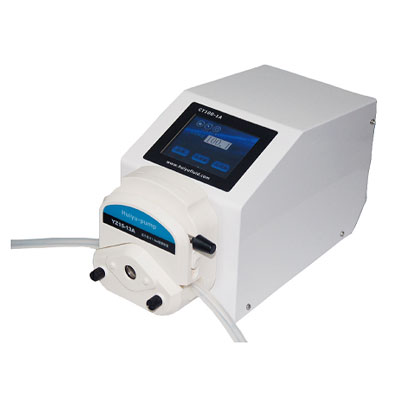

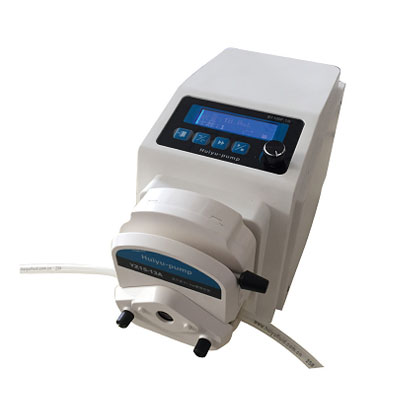

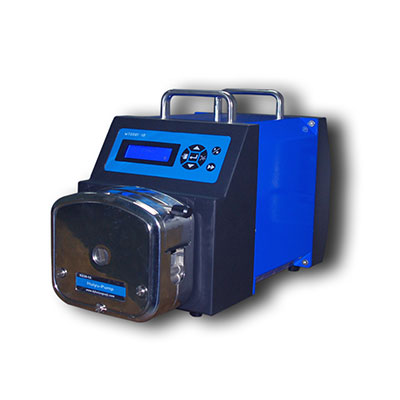

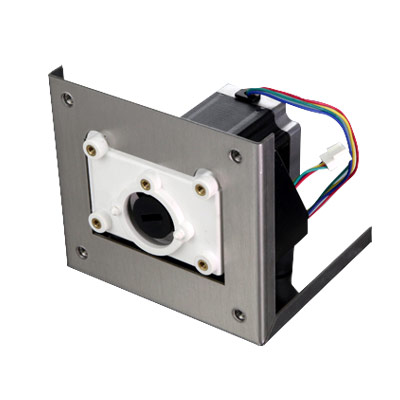

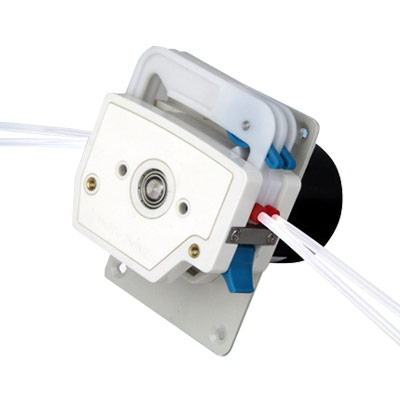

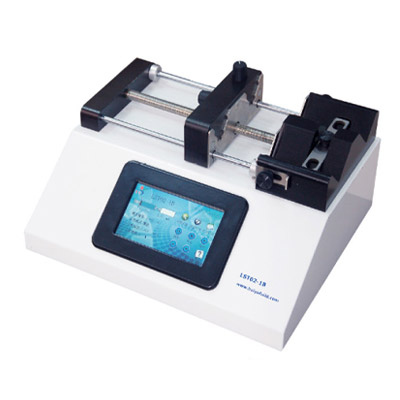

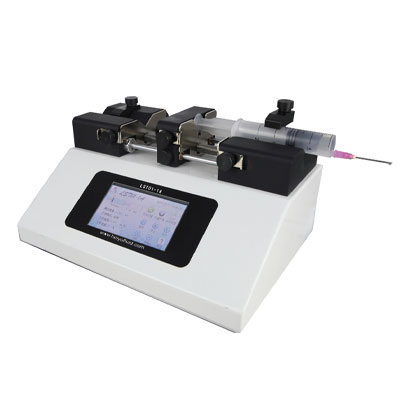

The electrostatic spinning device consists of four parts: high-voltage power supply, injection pump, spinneret, and receiver. Among them, the spinning device should be placed in a box with a metal shield, the laboratory syringe pump must be grounded, and the syringe pump and high-voltage electrostatic equipment cannot share a power source.

In bioengineering laboratories of colleges and universities, the laboratory syringe pump produced by Huiyu Company can operate stably and reliably under high-voltage electrostatic field, with stable and continuous injection speed, adjustable flow rate, flow calibration function, touch screen control, and spinning Produce uniform fibers and reduce the influence of beads on fiber performance.

您的位置:

您的位置:

400-0602-365

400-0602-365